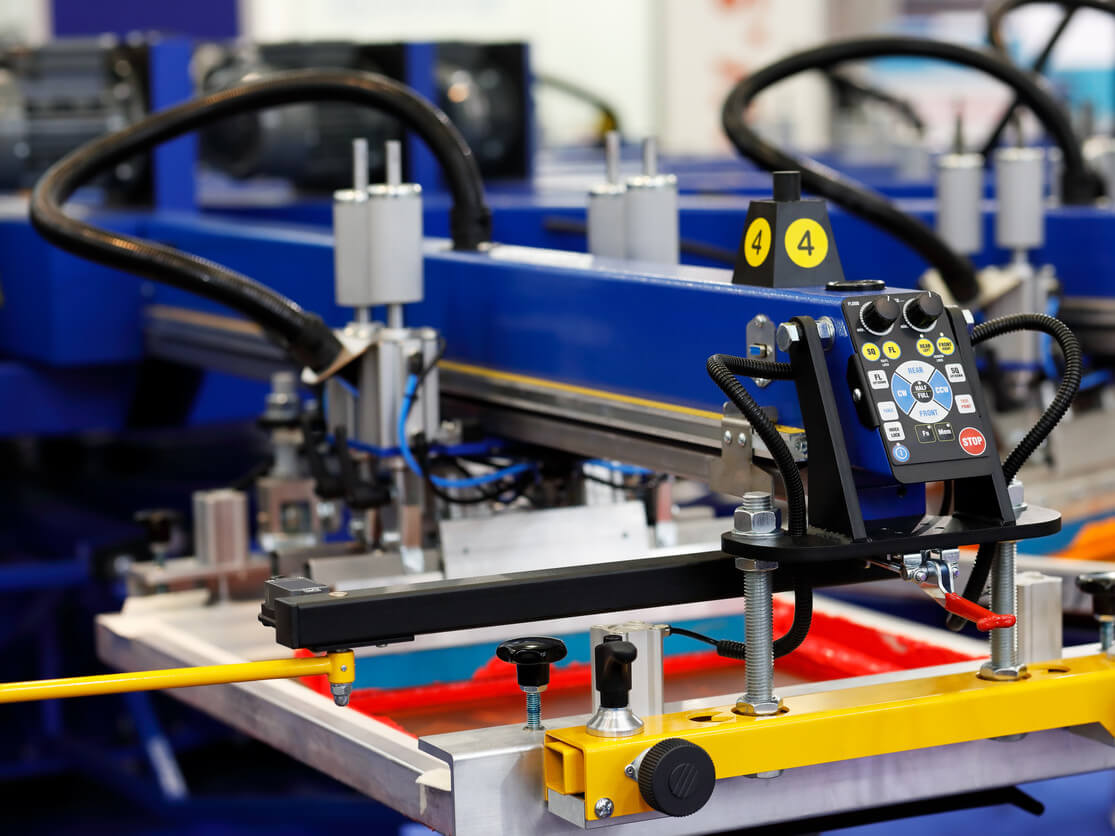

We use several different techniques and machines to create products for our clients. While there is definitely more than one way to create high quality t-shirt designs, the operation generally falls into either manual or automatic when it comes to screen printing. To give you an inside look at our industry, let’s look at manual vs. automatic screen printing for a better understanding of this operation.

The Difference

The biggest and most obvious difference in manual vs. automatic screen printing is the level of work on the person making the product. A manual machine requires someone to manually perform the tasks associated with screen printing such as printing the color, adjusting the color on a second pass by hand, rotating the carousel, and lifting the printing heads by hand. An automatic screen printer will remove all the extra work and let the machine perform it.

When looking at manual vs. automatic screen printing, there are a few pros and cons to both worth noting.

Pros Manual

- Allows for a more custom approach. With manual operation, the designer has the ability to adjust the end result in a range of ways during a run. This means one shirt may have a different appearance from the next in the run to create more of a custom appearance.

- More hands on. Since this option requires someone to manually perform many of the steps, it is more hands on which is a pro for a few reasons. For starters, if someone enjoys working with their hands, this is a great choice and could be seen as fun. It is also great because with a manual printer doing small batches, it is easier to catch and remedy any mistakes as opposed to a larger run. If a mistake is found, the person working the machine simply remedies it and resumes the rest of the batch.

- Ideal for small runs. When looking to only create a few or even just one item, manual is the better choice. This option allows for small batches to be made without the use of a larger, more complicated process.

Cons Manual

- More physical exertion. The simple fact of the matter is that a manual option takes more energy out of the person performing the task. This is especially important when working on big jobs because the person will quickly tire out from doing it all by hand.

- Requires more workers. If an operation is looking to produce larger batches, they will require a large workforce to do the manual screen printing. This will in turn run up costs due to labor.

- More likely to make mistakes. While doing it all manually does give more customization, there is also greater potential for mistakes. When a mistake occurs, it may even require the process to start from the beginning which sets schedules back and makes it take longer to produce a batch.

- Takes longer. A manual screen printing operation also takes longer in general. Since it is all done by hand and based on the speed and precision of the worker, it can take a long time to complete the project. It will also take a long time to do a larger batch run simply because you can only do one at a time and each one takes so long.

Pros Automatic

- Faster production. The biggest benefit of automatic screen printing is the faster rate of production. An automatic machine can print anywhere from 3,000-5,000 whereas a manual can only produce a couple hundred a day.

- Larger runs. Another major benefit of an automatic printer is that they complete larger runs because they are faster than manual options. In fact, many print on demand businesses without an automatic printer will turn down orders if the quantity is too large for them to handle manually.

- Consistent quality. An automatic screen printer offers a more consistent quality since it is automated. This means all the products in a batch will look the same in appearance with no variation between them.

- Reduces work force needed. Since an automatic machine does most of the work, it doesn’t require the workforce of manual set up. It allows a business to create large runs with just a few people manning the machines.

Cons Automatic

- Space required. One of the few downsides of an automatic screen printing system is that the machine tends to be larger than your typical manual option. When running a larger operation, a business may even have several machines set up so the space required is even greater.

- Less customization of a run. The only other major downside to an automatic machine is the loss of the customization or unique approach achievable when working with manual, but this may not be an issue since a lot of customers prefer a similar appearance in the products in a run.